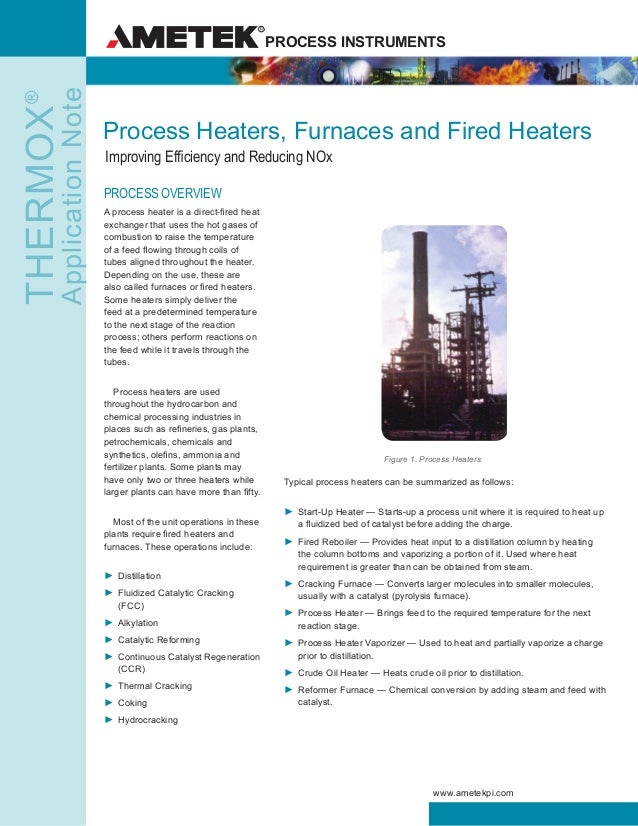

Fired heaters designed for refinery applications are generally designed for allowable average radiant heat flux q r which is one of the most closely watched design factors of fired heaters for given process application for determination of average radiant heat flux it is necessary as a first step to determine the radiant heat duty q r all of existing well established 1dquasi theoretical.

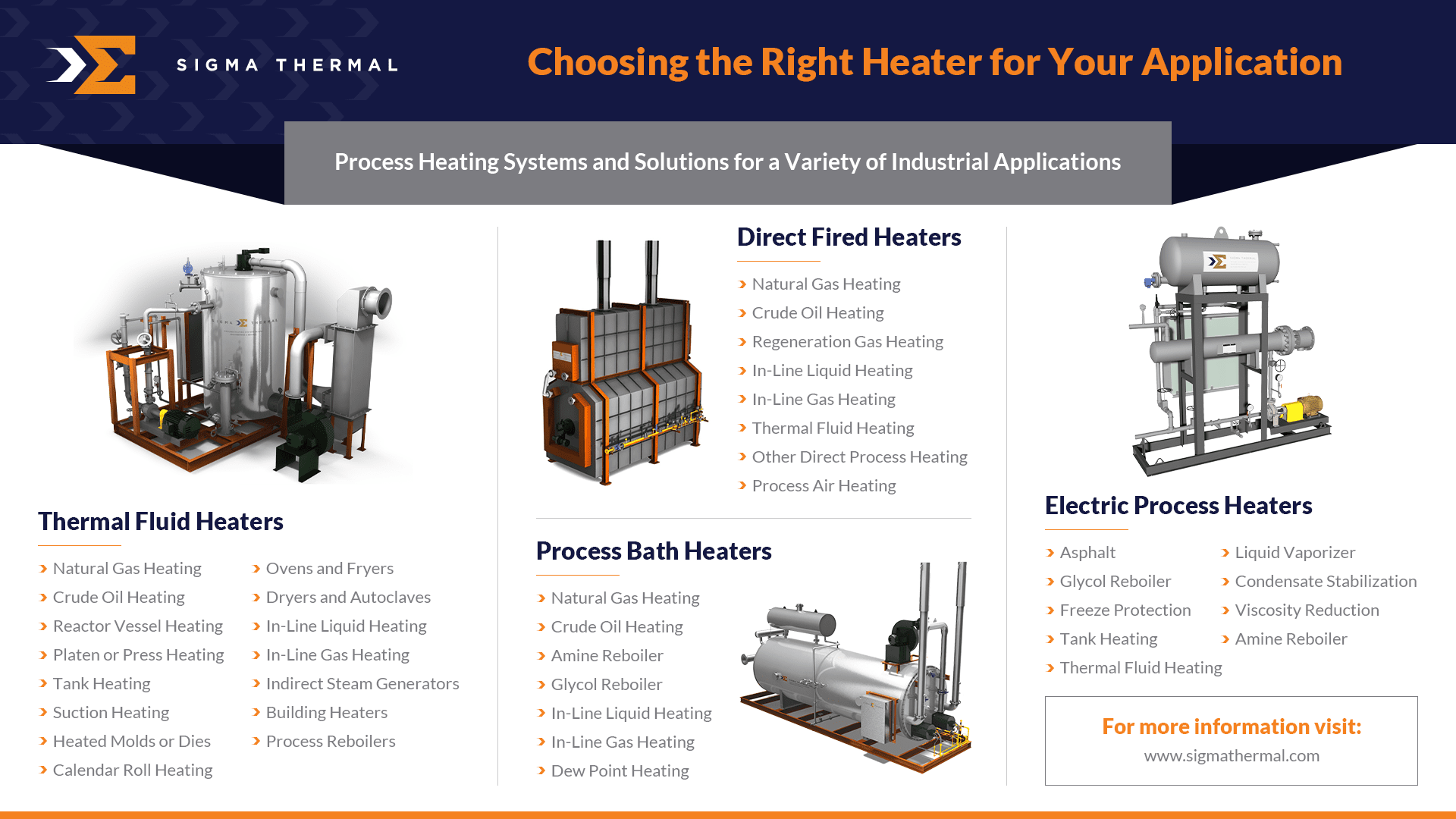

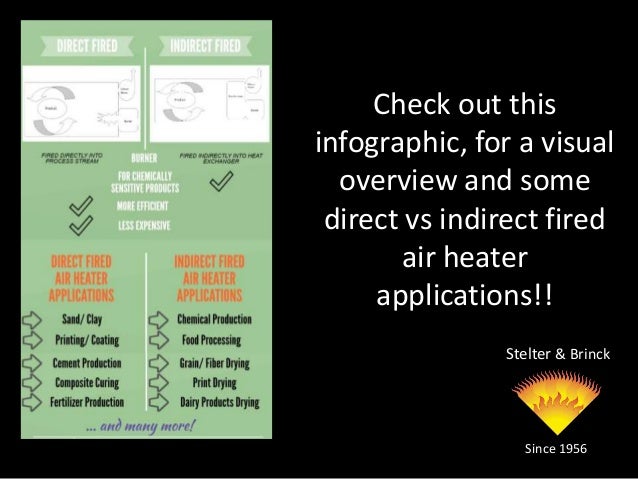

Direct fired heater applications.

We ve put together a video with some of our most common direct fired heater applications which you can see below.

We could consider direct fired heaters basically as custom designed equipment given that the heat is directly transmitted to the product of the process and any change in this characteristic could render the equipment ineffective for the new conditions of the process or even destroy the.

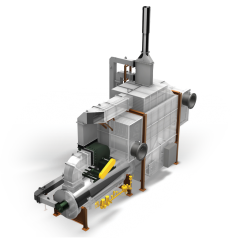

Radiant heat transfer can be undesirable in certain temperature sensitive applications as radiant heat transfer tends to be more intense and unevenly distributed around the coil surface.

Direct fired heaters are used for specific applications.

A convection style heater offers the benefits of a direct fired heater while eliminating some of the drawbacks associated with radiant heat transfer.

A direct fired heater or an industrial furnace uses the hot gases of combustion to transfer the heat to the liquids flowing in the heat exchange coils.