We offer a suitable deburring machine for punched laser or plasma flame cut parts in order to offer you the optimal machine solution we specifically focus on your parts and your edge processing requirements.

Different types sheet metal deburring machines.

This is also one of the most discussed methods of sheet metal deburring.

Their machines have the capability to finish parts as small as a 50 cent pieces and have very few components that when combined can be easily tailored to suit a variety of applications.

Whether thick or thin parts heavy or light burrs.

The cost of the manual file is more expensive the deburring efficiency is not very high and it is difficult to remove the complex cross hole.

The burrs of this type are created due to the heat produced by plasma or laser cutting machines.

First of all there is manual deburring.

It is an operation of cutting a whole piece from sheet metal.

Although sheet metals have their applications and know for their unique qualities there is no particular definition better than that.

Developing deburring and finishing standards.

The file is divided into two types.

This type of deburring is perfect for small metal pieces that may be burred in hard to reach places.

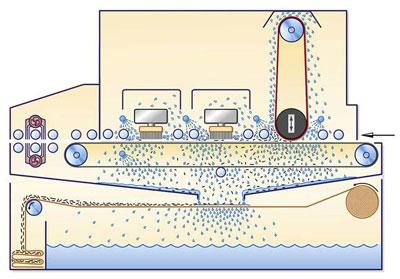

This is an automatic feed tough machine with a belt the machine will deburr and sand a radius to the sharp edge on cut out parts.

List of different types of sheet metals and their uses 1.

A punch and die is applied for this type of sheet metal operation.

The burred part of the metal sheet is dipped into a glycol solution or salt solution and exposed to electrical current.

The valgro classic series for deburring and finishing sheet metal and other flat parts that needs a radius edge.

Of these the first and the last type of.

These are again differentiated into two types rollover burrs and breakout burrs.

22 different types of lathe machine operations.

Stainless steel sheets metals.

In which enough scrap is left all around as shown in fig.

To begin you need to have a clear understanding of quality expectations the edge requirements identified through product drawings.

Material steel stainless steel aluminum copper titanium sheet and many other types of metal.

First of all there is manual deburring.

An outlook on various types of burrs.

Specialists utilize brushes or angle grinders to remove the burrs.

There are several different options for deburring sheet metal.

It s instead called a processing technology that is the handbook or metal workers.

In this method a metal plank or metal sheet is placed in a sealed chamber and burrs are removed through a combustive reaction.

The removal of burrs is carried out with the method of making punch mold worked on the punching machine.