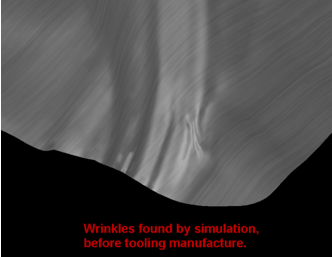

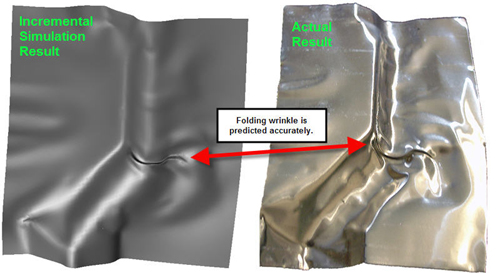

The flange of the blank undergoes radial drawing stress and tangential compressive stress during the stamping process which sometimes results in wrinkles.

Defects in sheet metal operation.

Wrinkles splits and springback are the three most common defects.

Identifying and resolving the most common defects in sheet metal forming solving common defects in sheet metal forming.

Sheet metalworkingforming on metal sheets strips and coils.

The first one is sheet metal cutting second one is sheet metal bending or forming and the last one is known as deep drawing in this article we mainly focus on sheet metal cutting operations and other two we will discuss into upcoming articles.

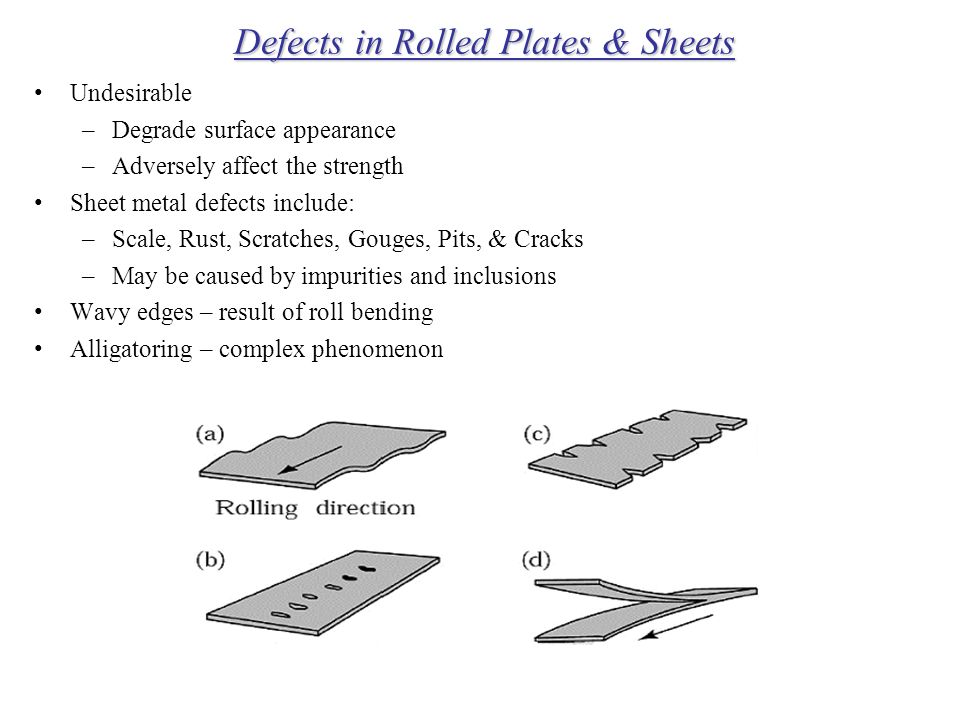

The rolling defects are mainly two types.

In cutting operations is relatively small usually 3 to 8 of sheet metal thickness.

One of the primary defects that occurs in deep drawing operations is the wrinkling of sheet metal material generally in the wall or flange of the part.

Rolling defects of after machined metals the rolled parts are more thicker than the required thickness of metal because of the rolls get deflected by high rolling forces apply.

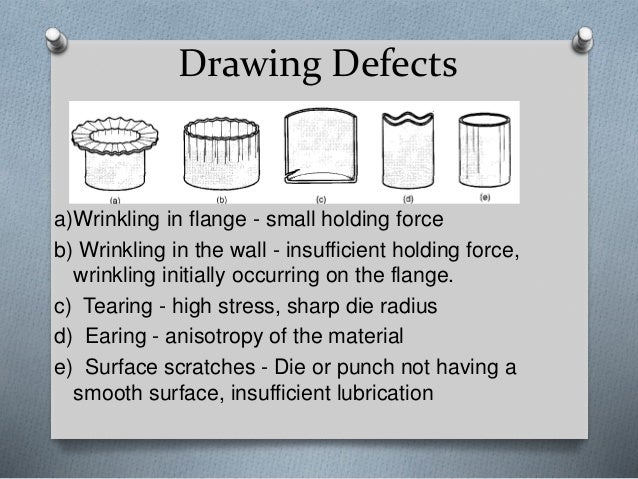

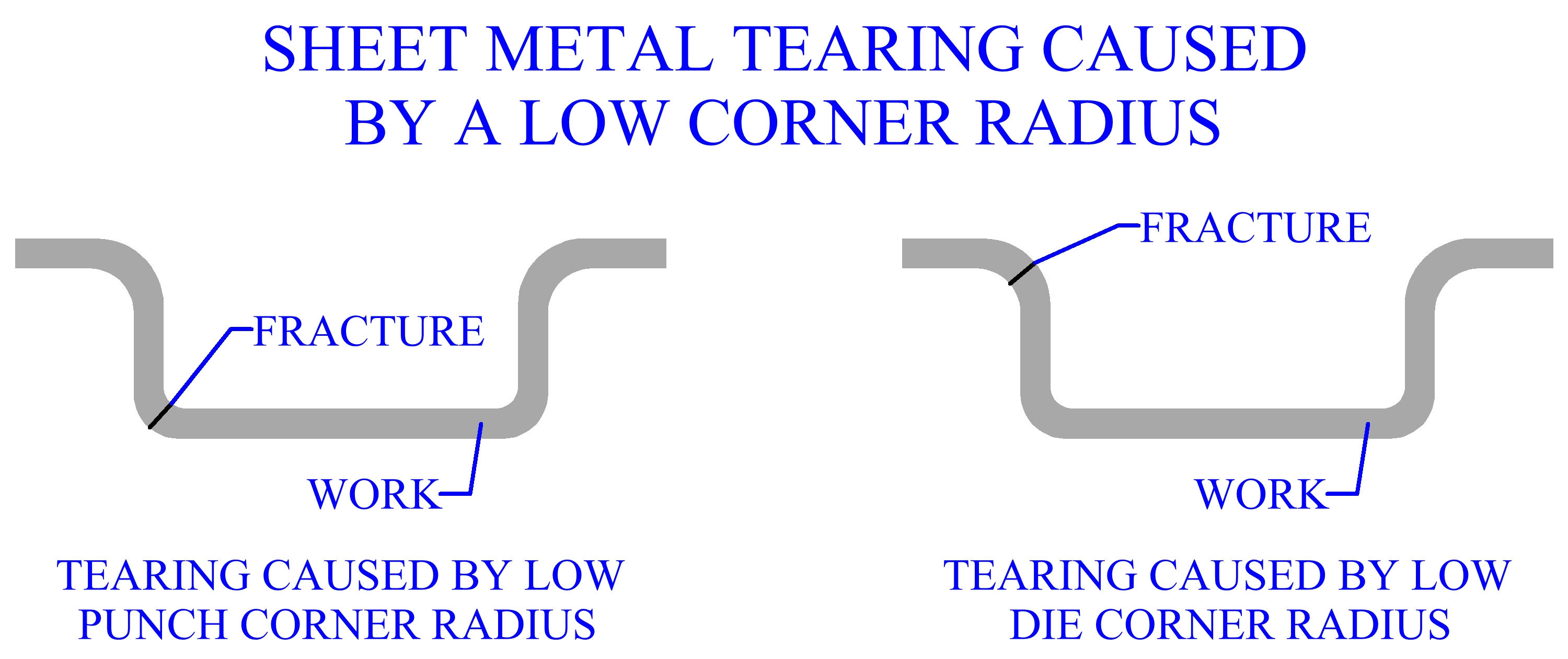

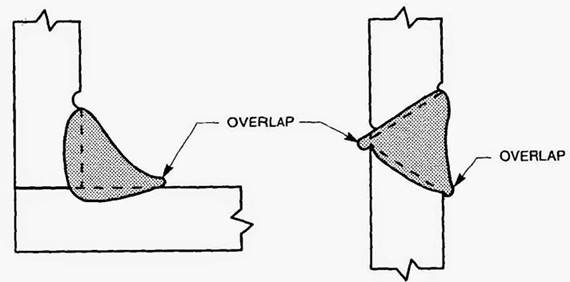

Defects in drawing wrinkling in the flange wrinkling in the wall tearing earing anistropy in sheet metal surface scratch.

Shearing not a forming process but a cutting process.

With the reliable technicians advanced equipment rigorous quality system rebond is committed to avoiding 6 defects in sheet metal forming.

Mainly sheet metal process can be divided into three types.

Clearance in deep drawing manufacture is greater than sheet thickness usually clearance values are 107 to 115 of sheet thickness.

Generally if experiencing wrinkles during production this could mean the wrong process was chosen.

Bending straining of a metal sheet to form an angle bend.

Other drawing operation redrawing drawing without a blankholder not cylindrical cups defects wrinkling in the flange wrinkling in the wall tearing earing anistropy in sheet metal surface scratch.

Drawing forming a sheet into a hollow or concave shape.

The process is normally a cold working process using a set of punch and die.